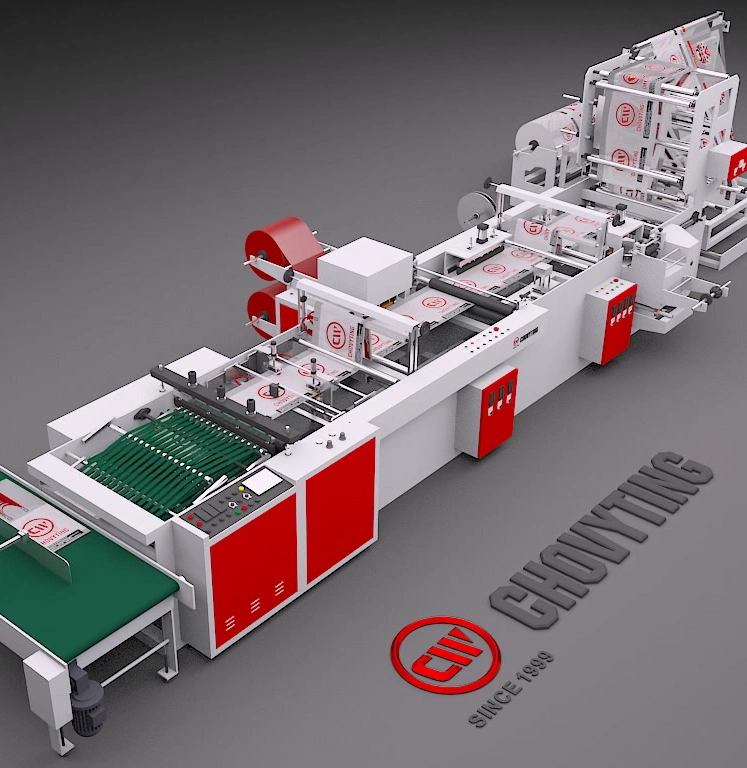

Factory Price 4 Functional Patch Drawstring Loop Handle Clothing Shopping Bag Making Machine for Taking out Bag

CW-800ZD fully automatic high speed carry bag making machine (4 function) Bag sample Detail ImagesCommon unwinding 1. Un

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | CW-800ZD |

| Speed | Medium |

| Continuous-Rolled | No |

| Sealing & Cutting | Heat-Sealing Heat-Cutting |

| Layer | Double |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Plastic Bag Making Machine |

| Air Cylinder | Shanko From Taiwan |

| Photocell | Leuze Germany |

| Servo Motor | Yaskawa- Japan |

| Main Motor | Cpg -Taiwan |

| Switch and Button | Idec-Japan |

| Solid State Replay | Fotek-Taiwan |

| Transport Package | Wooden with Plastic Film Wrapping |

| Specification | 8.2*3.1*1.87m |

| Trademark | CHOVYTING |

| Origin | Chnia |

| HS Code | 8401200000 |

| Production Capacity | 300sets/Year |

Product Description

CW-800ZD fully automatic high speed carry bag making machine (4 function)

| Model | CW-800ZD | |

| Length of bag-making | 250-750mm | |

| Width of bag -making | 250-600mm | |

| Top folding edge | 50-75mm | |

| Bottom gusset | 20-70mm | |

| Speed of bag-making | soft loop handle bag | 60pcs/min |

| patch handle bag | 60pcs/min | |

| poly draw handle bag | 65pcs/min | |

| die cut bag making | 80pcs/min | |

| Total power | 13kw | |

| Machine weight | 3500kg | |

| Machine dimension | 8.2*3.1*1.87m | |

| Aie compressior | 7HP | |

Bag sampleDetail ImagesCommon unwinding

1. Unwinding adopt pneumatic auto loading , max diameter of raw rolling material is φ600mm

2. Adopt magnetic powder tension control. Manual adjust the tension.

3. Unwinding shaft is heavy-chain plug axle

4. Unwinding with EPC Top folding and round bottom gusset device:

1.14mm high hardness steel plate top folding and round bottom guset

2.Special guide plate and roller ,which offer less friction fold

3.With flat press roller

4.More thin round disc bottom gusset

5.U style mould bottom molding

Patch handle bag device

1.Pneumatic control feeding

2.Turnabout cylinder control patch

3.With flying knife cutting fast

4.Special pattern sealing mould

5.Micro-motor driver patch go forward and back off

6.Base mould of patch device adopt whole steel plate Soft loop handle bag device

1.Double layer unwinder

2.The whole type steel plate base, and special support bag structure.

3.High quality oval sealing knife from up and down

4.Hydraulic skew angle feeding soft loop

5.90 degree turnabout gear rotary soft loop

6.Special oblique drag style rotary soft loop

7.Micro-motor driver soft loop handle go forward and back off

8.Centralize style air control systemHeat sealing handle punch

1.High hardness gear steel smooth pillar

2.Air outside waster film blower hopper

3.The whole style rotary 180 degree

4.High hardness alloy aluminium puncher base plate

Related Products

-

![High Speed Polythene 3 Layer Film Blowing Machine]()

High Speed Polythene 3 Layer Film Blowing Machine

-

![High-Speed Slitter Rewinder Slitting Rewinding Machine for Paper Roll Thermal Paper Stretch Film]()

High-Speed Slitter Rewinder Slitting Rewinding Machine for Paper Roll Thermal Paper Stretch Film

-

![Flexographic Printing Machinery Flexo Labels&Stickers Printing Press Flexo Printing Machine with Rotary Die Cutting Station and Sheeting Station Label Printer]()

Flexographic Printing Machinery Flexo Labels&Stickers Printing Press Flexo Printing Machine with Rotary Die Cutting Station and Sheeting Station Label Printer

-

![(SCR75G Series) Hot Sale Oil Free Screw Air Compressor German Technology Direct Driven 7bar to 12.5bar Rotary Industrial High Performance]()

(SCR75G Series) Hot Sale Oil Free Screw Air Compressor German Technology Direct Driven 7bar to 12.5bar Rotary Industrial High Performance