High Speed Polythene 3 Layer Film Blowing Machine

the whole machine is square structure traction inverter control, host frequency conversion control, (optional fan freque

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | CHSJ-ML-ABC |

| Type | Three-Layer Co-extrusion Film Blowing Machine |

| Raw Material | Mixing |

| Maximum Folding Width of Film | 1200mm |

| Screw Diameter | 65mm |

| Automation | Automatic |

| Computerized | Computerized |

| Machine Weight | 12T |

| Certification | CE, ISO9001:2008 |

| Film Width(Folding Diameter) | 300-1800 |

| Film Thickness(mm) | 0.007-0.05 |

| Extrusion Capacity | 150-380 Kg/H |

| Winding Speed M | 30-150/Min |

| Diameter of Screw | 65/75/65 mm |

| Transport Package | Wooden-Box / Nude |

| Specification | SGS CE ISO |

| Trademark | Chengheng |

| Origin | China |

| HS Code | 8477300000 |

| Production Capacity | 100 Sets/Year |

Product Description

the whole machine is square structure

traction inverter control, host frequency conversion control, (optional fan frequency control, winding frequency control) 100% inverter motor + frequency converter control

Full enclosed overtemperature cooling device

brand Industrial electricity

Lambdoidal board

Optional accessories

Auto Ioader

Corona treater

Air compressor

Mechanics screen changer

Double winding

360°Die rotary device

full-automatic winder and lap changing equipment

| Model | ABC-45-50-45/1200 ABC-50-55-50/1400 ABC-55-65-55/1600 ABC-65-75-65/1800 | |

| Width of the film | 250-1100mm 300-1300mm 500-1500mm 500-1700mm | |

| Thickness of the film | 0.006-0.15mm | |

| The max output | 135kg/h 155kg/h 185kg/h 205kg/h According to different width,thickness of film, die size and raw material characteristics to change | |

| Raw material | HDPE/LDPE/LDPE/RECYCLE/CACO3 | |

| Power consumption | 28kw/h 32kw/h 35kw/h 40kw/h | |

| Weight | 4200kg 5200kg 9800kg 10200kg | |

| Overall dimension(L*W*H)m | 6.5*2.7*5.8 6.5*3*6.2 6.5*3.8*6.8 6.8*4*7.5 | |

| Extruder unit | ||

| Diameter of screw | Φ45/50/45 Φ50/55/50 Φ55/65/55 Φ65/75/65 SACM645 wearproof Alloy steel,five years guarantee | |

| L/D ratio of screw | 30:1 | |

| Rotation speed of screw | 10-120r/m | |

| Barrel Fan | Zone 3 barrels install over-temperature fan | |

| Gear box | 146# 173# 200# 225# Extruder special hard gear reducer,tooth grinding teeth hardened, internal and external oil circulation system | |

| Main motor | 15kw 22kw 30kw 37kw 100% Original three-phase variable frequency motor Equipped with inverter control | |

| Die head unit | ||

| Die diameter | 60mm 80mm 120mm 250mm 360mm With 40Cr steel forging finishing, eight feed trough runner,Uniform flow channel,blown plasticizing effect | |

| rotary electric machine motor 0.75kw | ||

| rotation mode 360 degree | ||

| Cool unit | ||

| Air ring type | LDPE double vents vacuum air ring HDPESingle outlet air ring | |

| Air ring material | High quality Taiwan cast aluminum alloy air ring | |

| Bellow power | 4kw 5.5kw 7.5kw 11kw Shanghai production of high-pressure mute fan | |

| Traction unit | ||

| Width of take up roller | 1200mm 1400mm 1600mm 1800mm | |

| Traction roller material | silicone roll NBR roller | |

| Take up motor | 1.5kw 2.2kw 3.0kw Installation of RV series reducer variable frequency motor inverter control | |

| Take up speed | 100m/min | |

| constant tension traction motor | 1.5kw frequency control 10N.m torque control | |

| width of traction roll | 700mm 900mm 1200mm 1400mm | |

| Embossing roller | hot embossing unit cold embossing unit | |

| Lambdoidal board | Wooden flannel wrapped Aluminum roller guide | |

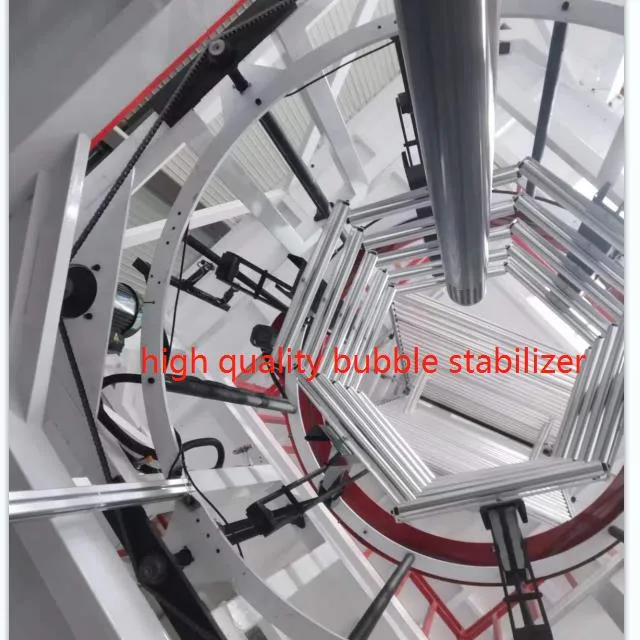

| Bubble stabilizing ring | Electric aluminum roller guide Manual wood floor | |

| Guide roller | Aluminum guide roller (HV300-HV700) surface treatment | |

| Winding unit | ||

| Winding type | Surface friction rewinding, manually change the volume | |

| Drive type | Torque motor equipped RV reducer | |

| Film expanding roller | Smoothing roll | |

| The second traction part | Independent torque control constand tension control | |

| Computer control type | 7-inch touch screen + process control system Automatic air supply device | |

Our Advantage:

1. First-class and professional service team offer one-stop intimate service. 18 senior technical experts, more than 20 after sales service staff.

2. No charge for training the technician, let you have nothing to worry about!

3. Five yearafter-sales service and mechanical parts lifetime warranty.

4. Life-long free for offering all kinds of technical service and 24 hours after service.(no worry about the time differences)

Order step

step1. Please let us know which product you like. the model and size, the offers will be sent to you within 24 hours.

step2. We make proforma invoice (PI) for you.

step3. Please check and confirm the PI

step4. Once we confirmed the order, please pay it soon.

step5. After payment, all goods will be sent to you in the delivery time.