Corrugated Box Making Machine Carton Printing Slotting Die Cutting Machinery Flexo Printing Machine

Full automatic corrugated box making machine Specification: DONGGUANG XINGLONG PACKAGING MACHINERY CO., LTD. is speciali

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | FAY1022 |

| Brand | Xinglong |

| Speed | 120PCS/Min |

| Power | 15kw |

| Weight | 18 Tons |

| Feeding Type | Lead Edge |

| Transport | by Sea |

| Package | Film.Container |

| Name | Printing Slotting Die Cutting Machine |

| Transport Package | Film, Container |

| Specification | 922 1224 1226 1424 1426 |

| Trademark | xinglong |

| Origin | China |

| HS Code | 8401309000 |

| Production Capacity | 200 Sets Per Year |

Product Description

Full automatic corrugated box making machine

Specification:

| Model | GYKM922 | GYKM1224 |

| Machine inside width (mm) | 2400 | 2600 |

| Max feeding paper siz(mm) | 900*2200 | 1200*2400 |

| Max effective printing size(mm) | 900*2000 | 1200*2200 |

| Min coverage size(mm) | 350*700mm(full plate printing) | 350*700mm(full plate printing) |

| Max die cutting space(mm) | 900*2150 | 1200*2350 |

| Design speed | 250pcs/min | 200pcs/min |

| Working speed | 200pcs/min | 180pcs/min |

| Standard Thickness of printing plate | 6mm | 6mm |

| Printing precision | ±0.5mm | ±0.5mm |

| Thickness of cardboard | 1.2-9mm | 1.2-9mm |

| Wall thickness | 50mm | 50mm |

| Main motor power | About 30kw | About 30kw |

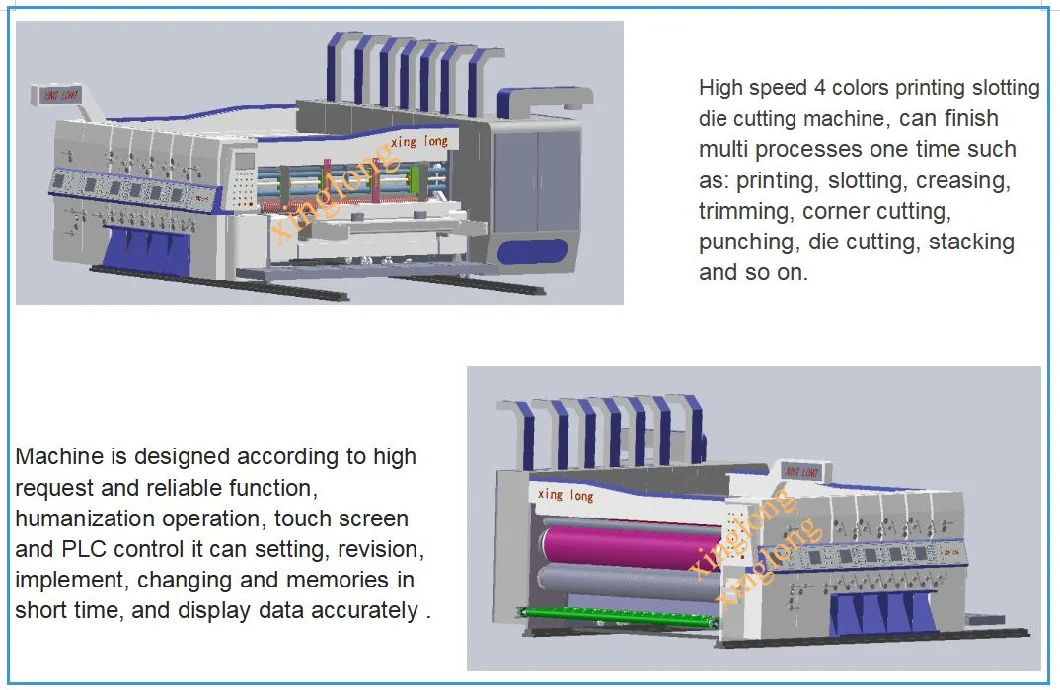

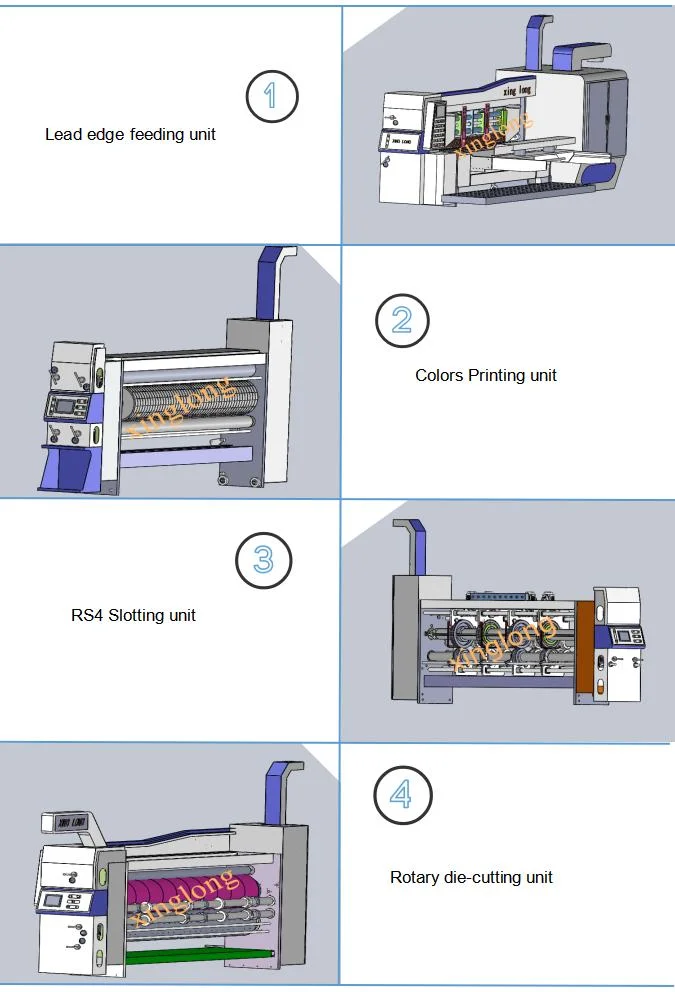

- The machine can finish multi processes one time such as: printing, slotting, creasing, trimming, corner cutting, punching, die cutting, stacking and so on.

- Machine is designed according to high request and reliable function, humanization operation, it can setting, revision, implement, changing and memories in short time, and display data accurately .

- All of drive rollers are made of high quality steel, hard chrome plated the surface with grinded.

- Main drive gears adopt high quality steel with heat treatment with grinded, adopt cross slip system connect each gear, keep gear fix position, ensure transmission precision.

- The main drive roller adopt keyless connect, decrease the connection gap, ensure printing precision.

- The machine adopts sealed spray lubrication for gear system, engineer oil automatic balance device; keep the oil level equal in each unit.

- Motorized digital phase adjustment with "automatic zero return" and "memories" function ( options: PLC control with touch screen)

- The machine adopts lead edge (or kick feeding), low demand for the cardboard, fast.

- Main motor is VFD, working stability, low power consumption.

DONGGUANG XINGLONG PACKAGING MACHINERY CO., LTD. is specialized in the production of various kinds of carton equipments of the well-know enterprise. Factory for over twenty years, we introduced advanced technology at home and abroad, developing and manufacturing products, has been well received by customer. We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary printing machine, single facer, rotary die cutter and other corrugated cardboard production equipment .products are distributed Russia ,the Middle East, Africa, Southeast Asia, EU and other countries and throughout the country. Product quality and enterprise reputation get the high praise at home and abroad. Over the years the company take "the quality first" "integrity-based" corporate purpose always meet user're-equipments as our sole purpose, providing the products with excellent quality, professional technology. Our company is willing to cooperate with domestic and foreign insight, strive for innovation, coexist win-win, hand in hand altogether will create packaging future.

1.

Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2.

Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery equipment, it's difficult to send you samples, if you have any questions about the products, please feel free to contact us for more detail, we are glad to provide you more information such as specifications, video, etc.

3.

Q: How does your factory do regarding quality controlling?

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

4.

Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.

Related Products

-

![Plastic PE Film Blowing Machine Extruder Blown Film Machine]()

Plastic PE Film Blowing Machine Extruder Blown Film Machine

-

![Flexographic Printing Machinery Flexo Labels&Stickers Printing Press Flexo Printing Machine with Rotary Die Cutting Station and Sheeting Station Label Printer]()

Flexographic Printing Machinery Flexo Labels&Stickers Printing Press Flexo Printing Machine with Rotary Die Cutting Station and Sheeting Station Label Printer

-

![(SCR75G Series) Hot Sale Oil Free Screw Air Compressor German Technology Direct Driven 7bar to 12.5bar Rotary Industrial High Performance]()

(SCR75G Series) Hot Sale Oil Free Screw Air Compressor German Technology Direct Driven 7bar to 12.5bar Rotary Industrial High Performance

-

![Diesel Screw 185 Cfm Portable Air Compressor for Jack Hammer]()

Diesel Screw 185 Cfm Portable Air Compressor for Jack Hammer