Plastic&Paper Double Stand up Zipper Doypack Pouch Making Machine

Use: It is an ideal Bag making machine to producing three-side sealing bags, stand up pouch, zipper bag, stand up pouch

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | YEZD-600ZL |

| Sealing & Cutting | Heat-Sealing Cold-Cutting |

| Layer | Double |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Plastic Bag Making Machine |

| Servo Motor on Stand up Pouch Machine | 3PCS |

| Brand of Servo Motor on Bag Machine | Panasonic |

| Material of Bag Making Machine | Baogang Steel |

| PLC on Bag Making Machine | Panasonic |

| Transport Package | Bag Making Machine Wrap with Film,Fix in Container |

| Specification | bag making machine was according to CE standard |

| Trademark | Y. E |

| Origin | Zhejiang |

| HS Code | 8441200000 |

| Production Capacity | 10sets Zd-600zl Bag Making Machine Per Month |

Product Description

Use:It is an ideal Bag making machine to producing three-side sealing bags, stand up pouch, zipper bag, stand up pouch with zipper, with 3 servo motor. Material: Laminated Film As; LDPE, CPP, MCPP, AL, NYLON, PP etc.

Featrues:

1. Whole machine controlled by central PLC control system with touch screen. More stable performance, easy for operation and maintenance. Chinese and English interface language can be changed easily. 2. Constant auto-tension control for unwinding, EPC edge alignment, AC inverter constant speed auto material feeding. 3. Imported double servo-motor material traction control system4. Main motor for up-down sealing and pressing equipped with inverter. 5. PID for sealing bar temperature adjustment, no touch auto control, centralized setting in man-machine interface. 6. Equipped with Pneumatic multi-function auto punching device, trim cutting and auto rewinding and static eliminator 7. Temperature adjustment range: 0~300ºC 8. Counter: quantity, batch accumulation, pre-set available. 9. Operation Method: by length fixation control and/or by photocell tracking control. 10. Punching device: working rhythm can pre-set as continuous, interval or stop, punching time can be pre-set. 11. Material Skip Feeding: 1-6 times available. 12. Batch Conveying Function available, the quantity of batch can be pre-set.

Main Parameters:

| 1 | Produced Bag Type | 3-side sealing, stand up pouch, zipper bag, stand-up zipper pouch |

| 2 | Unwinder Max.Size | Width Max=1250mm, Diameter Max=600mm |

| 3 | Material Type | Laminated Film As; LDPE, CPP, MCPP, AL, NYLON, PP etc. |

| 4 | Bag Size | Max. Length 400mm ( more than 400mm, multiple Infeed 6 times )Max.Width 600mm |

| 5 | Machine Speed | 150t/min |

| 6 | Unwind Line Speed | ≤ 40 m/min |

| 7 | Main Motor | 3.5 KW (Taiwan, with inverter Japan Yaskawa) |

| 8 | Infeed Drive & Motor | Front Infeed 1kw AC Servo (MITSUBISHI)Middle Infeed 1.5kw Ac Servo(MITSUBISHI)Back Infeed 1kw AC Servo (MITSUBISHI ) |

| 9 | Model of Control System: | Panasonic PLC (Made in Japan) high speed bag making control system. |

| 10 | Temperature Control | PC Control 24 set. ± 2ºC |

| 11 | Temperature control range: | environmental temperature to 300ºC |

| 12 | Horizontal Heater | 3 units, heating up and down, 640mm |

| 13 | Horizontal Cooling | 2 units, cooling, 640mm |

| 14 | Vertical Heater | 5 units, 800mm |

| 15 | Vertical Cooling | 5 units, 400mm |

| 16 | Zipper heating | 2 units, 640mm |

| 17 | Zipper cooling | 2 units, 330mm |

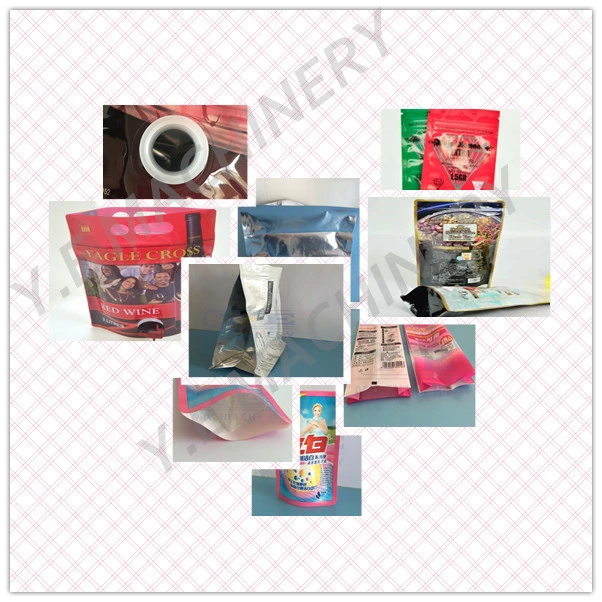

Laminated pouch samples we can produce:

1) Self-standing bag-in-box wine bag, with tapping vlave on-line2) flat bottom pouch with/without zipper.3) Stand up pouch zipper pouch4) Single-web stand up zipper pouch5) Zipper pouch6) Three side sealing pouch, central sealing pouch, side sealing pouch7) Four side sealing pouch8) Aluminum foil pouch

Machine details:

Stainless steel machine cover, clean and safe for food package:

Test run stand up pouch (single web and insert bottom):

Shipment and loading of bag making machine:

Related Products

-

![Automatic Label Flexo Printing Machine with Laminating+Rotary Die Cutting Slitting+Sheeting Station/Paper Cup/ Film Sticker Flexographic Printer Cutter Slitter]()

Automatic Label Flexo Printing Machine with Laminating+Rotary Die Cutting Slitting+Sheeting Station/Paper Cup/ Film Sticker Flexographic Printer Cutter Slitter

-

![1000mm PE Plastic Double Layer Three Layer Stretch Wrap Film Making Machine Hengtuo Machinery]()

1000mm PE Plastic Double Layer Three Layer Stretch Wrap Film Making Machine Hengtuo Machinery

-

![Multi-Layer Layer Co-Extrusion LDPE HDPE PE Film Blowing Machine Plastic Extruder Biodegradable Plastic Blown Film Extrusion Machine]()

Multi-Layer Layer Co-Extrusion LDPE HDPE PE Film Blowing Machine Plastic Extruder Biodegradable Plastic Blown Film Extrusion Machine

-

![Highly Brand R22/R410A/R32 50Hz/60Hz 220V /208/ DC Inverter Rotary Compressor]()

Highly Brand R22/R410A/R32 50Hz/60Hz 220V /208/ DC Inverter Rotary Compressor