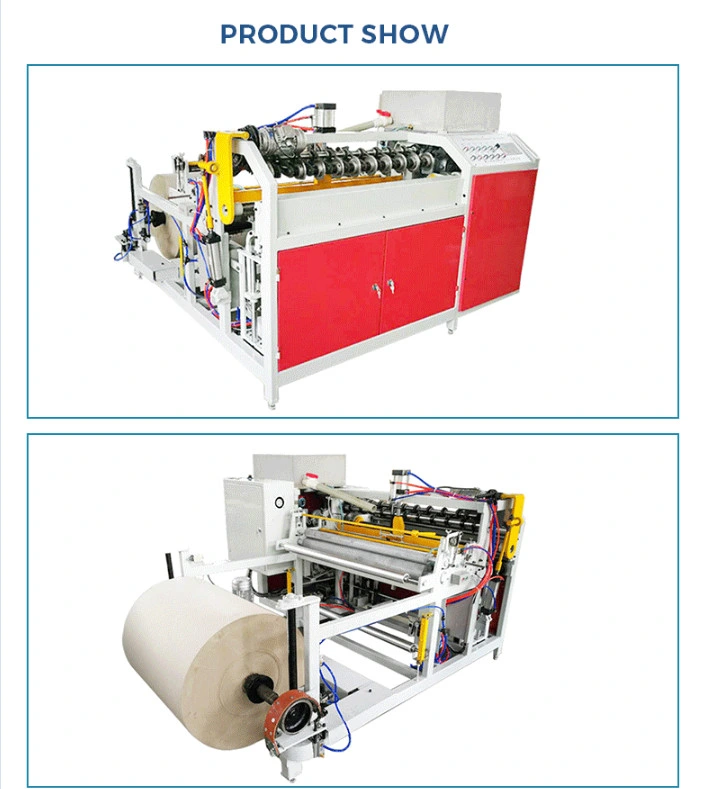

Textile Parallel Paper Tube Making Machine, Small Parallel Tube Making Machine for Stretch Film

YDF-16-76 Parallel paper tube making machine Product Description Parallel Paper drum Making Machine for paper barrels is

Send your inquiryDESCRIPTION

Basic Info

| Type | Parallel Type |

| Paper Core Usage | Industry |

| Gumming Type | Double Side |

| Layers of Roll Paper | 2 - 8 |

| Reelpipe Speed | 8-12times/Min |

| Wall Thickness of Paper Tube | 1.5-10mm |

| Certification | ISO9001 |

| Condition | New |

| Machine Type | Automatic Paper Tube Machine |

| Main Machine Power | 3kw |

| Cutting Machine Power | 5.25kw |

| Inner Diameter | 16-76mm |

| Gluing Type | Double Side Gluing |

| Finished Paper Tube Length | Adjustable Length Freely |

| Warranty | 1year |

| Transport Package | Conventional Dust-Proof Packing |

| Specification | 3000*1700*1300 |

| Trademark | YDF |

| Origin | China |

| Production Capacity | 50 Sets/Month |

Product Description

YDF-16-76 Parallel paper tube making machine

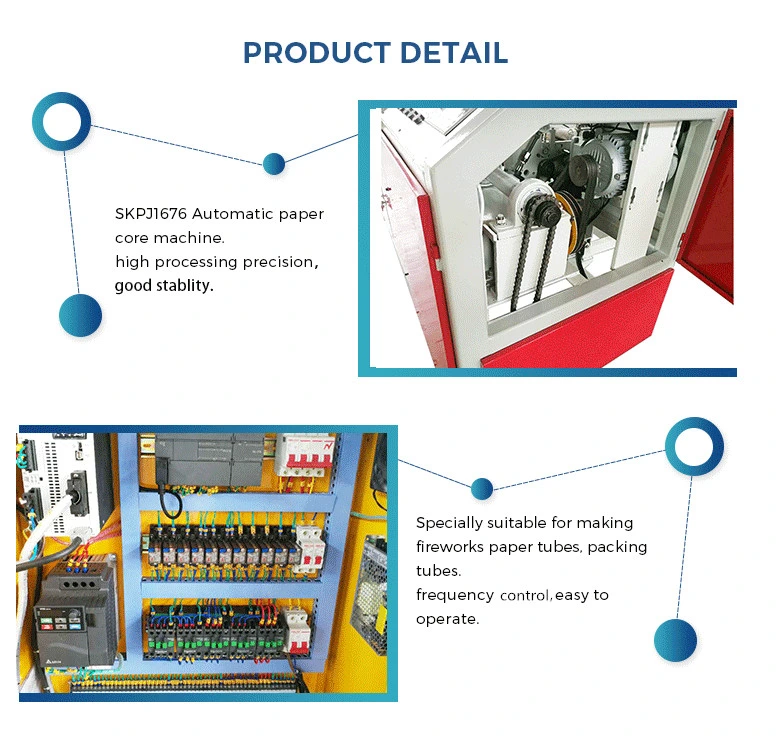

Product DescriptionParallel Paper drum Making Machine for paper barrels is used to manufacture cylindrical Fibre Drums using Kraft Board. These drums are used to pack bulk drugs, chemicals, dyes, pharmaceuticals, engineering, consumer goods, adhesives etc. In Textile Mills the fibres are also transported through these drums. Fibre Drums are the most preferred option wherever there is a need for a cost-effective, light weight but strong packing material. This machine is used to manufacture spirally wound paper tubes using various plies and glue.

Packaging & Shipping

Our Services

1.The business contact on both sides will reply within 2 hours .

2.During warranty period, the company provide the relevant technical services for free,Such as equipment quality problem resulting from the design and manufacturing equipment, which the company will be responsible for replacement and maintenance.

3.After the expiration of the warranty, our company provide customers with a lifelong technical service and spare parts with preferential price and efficient manner over a long period of time.

Company Information

Our company has several paper machine manufacturing enterprises and keeps a long-term and stable cooperation with the first-class large paper machinery manufacturers in the world.Our company can provide for global customers with paper tube machine,tissue paper machine, office supplies paper machine, packaging paper machine, white board paper machine with different types,high quality,energy conservation and environmental protection and pulping equipment, paper processing equipment and various accessories, spare parts,consumables.

FAQ

1.How to install and maintain the machine?

A: Firstly,we will provide the installation guild with the machine for your reference.

Secondly,our company is responsible for training production workers for you, ensuring that the workers will be independent operation.

2.How can we get the matching accessories or wearing parts conveniently?

A: During the warranty,Our company can replace the accessories for free .Out of warranty,we can provide them at the preferable price .In fact,the wearing parts are standard parts that you could get it in your country at your convenience.

3.Why would I choose your company?

A: Firstly,Our company has rich paper machine design and experience, and is the collection of paper making machinery research, design, manufacture, installation,commissioning and service, becoming one of the multi-functional enterprise.

Secondly,our company could provide the marvelous after-sale services, which is responsible for all installation and debugging, and training the production workers ,ensuring that the workers will be independent operation.

Thirdly,our company persist in the slogan "Customer's satisfaction is our standing pursuit".

Warm Tips

1.Before installation,you should check that equipment's model and dimension are all right with the parts complete d and level remaining.

2.Before the debugging of installation,Checking each part is correct, lubrication supply normal.water, electricity values reaching the standard.

3.During Operation,you should pay attention to keep daily inspection, cleaning and oiling.and then examine and repair regularly.

Related Products

-

![Fresh Keeping Film Cling Film Stretch Film Rewinder Machine]()

Fresh Keeping Film Cling Film Stretch Film Rewinder Machine

-

![Brand New Roll to Roll Flexo Printing Machine 8 Color Price]()

Brand New Roll to Roll Flexo Printing Machine 8 Color Price

-

![PE Stretch Film Rewinder POF PVA PVDC Pec Protective High Pressure PVC Wire Cling Film Rewinding Machinery]()

PE Stretch Film Rewinder POF PVA PVDC Pec Protective High Pressure PVC Wire Cling Film Rewinding Machinery

-

![Ht-300 Semi Auto Stretch Film Cling Film Rewinding Machine Rewinder Machine]()

Ht-300 Semi Auto Stretch Film Cling Film Rewinding Machine Rewinder Machine