Cm-Ab65 PLA Pbat Degradable Plastic HDPE Blown Stretch Film Making Machine

Overview Package size per unit product 600.00cm * 200.00cm * 400.00cm Gross weight per unit product 4500.000kg CM-AB65 P

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | CM-AB65 |

| After-sales Service | Local Service Available |

| Warranty | 2 Years |

| Type | Three-Layer Co-extrusion Film Blowing Machine |

| Raw Material | Post-Consumer/Post Industry/in-House Plastic Waste |

| Maximum Folding Width of Film | 1000-1800 |

| Screw Diameter | 65 |

| Automation | Automatic |

| Computerized | Computerized |

| Machine Weight | Customzied |

| Certification | CE, ISO9001:2008 |

| Machine Type | Film Blowing Machine |

| Electric Components | ABB, Ls, Omron, or Customized |

| Control | P.L.C Control |

| Sample/Service Manua | Available |

| Factory Location | 2 Hours Drive From Shanghai |

| After-Sale Service | Free Spare Parts |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Material | Iron |

| Capacity (Kg/H) | 100-220 |

| Die Size (mm) | 380 |

| MOQ | 1PC |

| Transport Package | Wooden Pallet |

| Specification | Customzied |

| Trademark | ACERETECH |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 8477209000 |

| Production Capacity | 10 Set/Sets Per Month |

Packaging & Delivery

Package size per unit product 600.00cm * 200.00cm * 400.00cm Gross weight per unit product 4500.000kgProduct Description

CM-AB65 PLA PBAT Degradable Plastic Hdpe Blown Stretch Film Making MachineProduct Description

Aceretech mainly focusing on R&D, manufacturing of high-end film blowing machines, provides cost-effective blown film machines and professional engineering film blowing service to markets. The typical film blowing machines Aceretech provides are: single layer blown film machines, AB double layer film blowing machines, ABA/ABC three layers blown film machines, ABCDE/ABCBA five layers film blowing machines, specialized agricultural films blowing machines and super wide industrial films making machines for materials of LDPE/LLDPE/PP/EVA/PLA/PBAT etc.

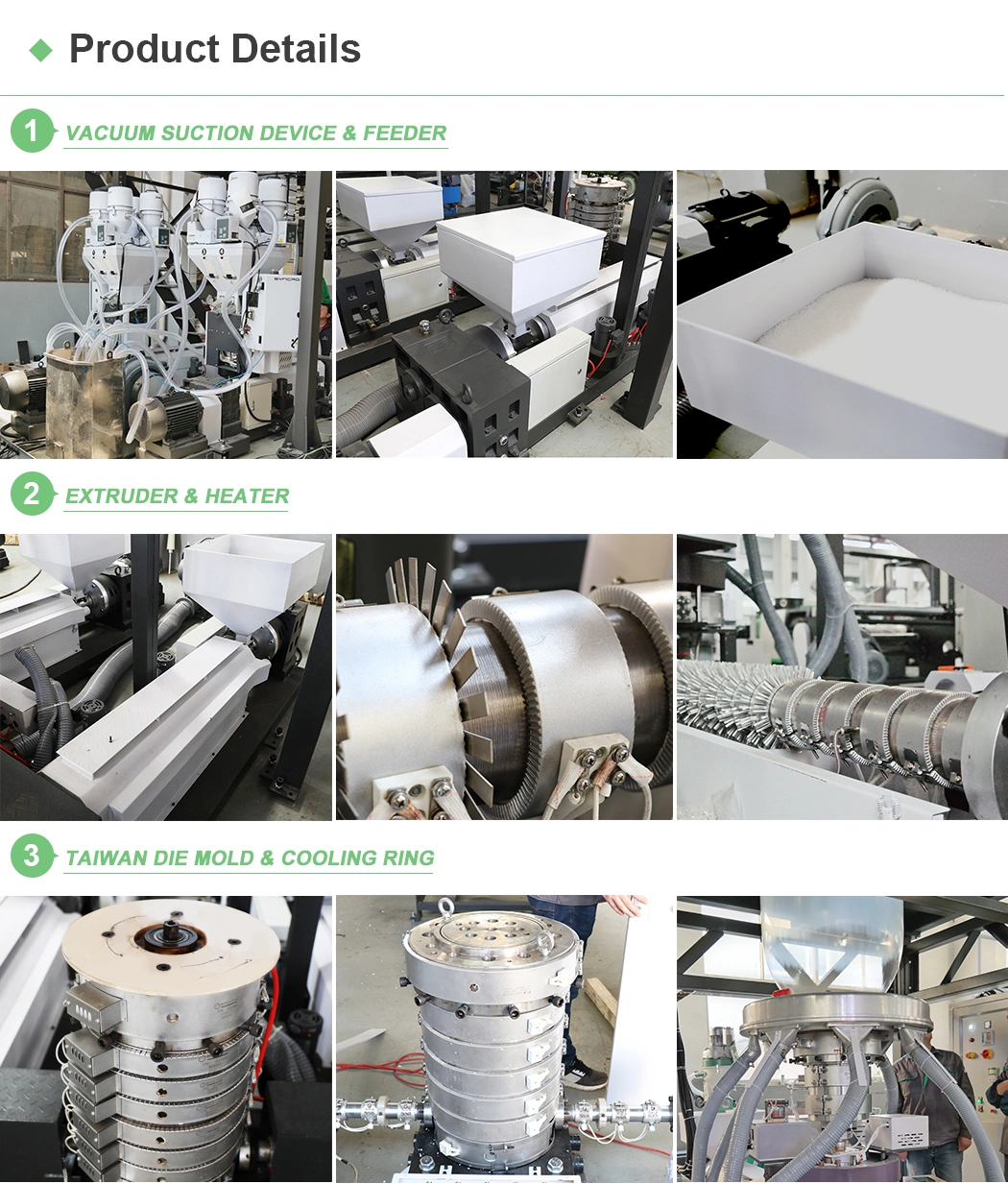

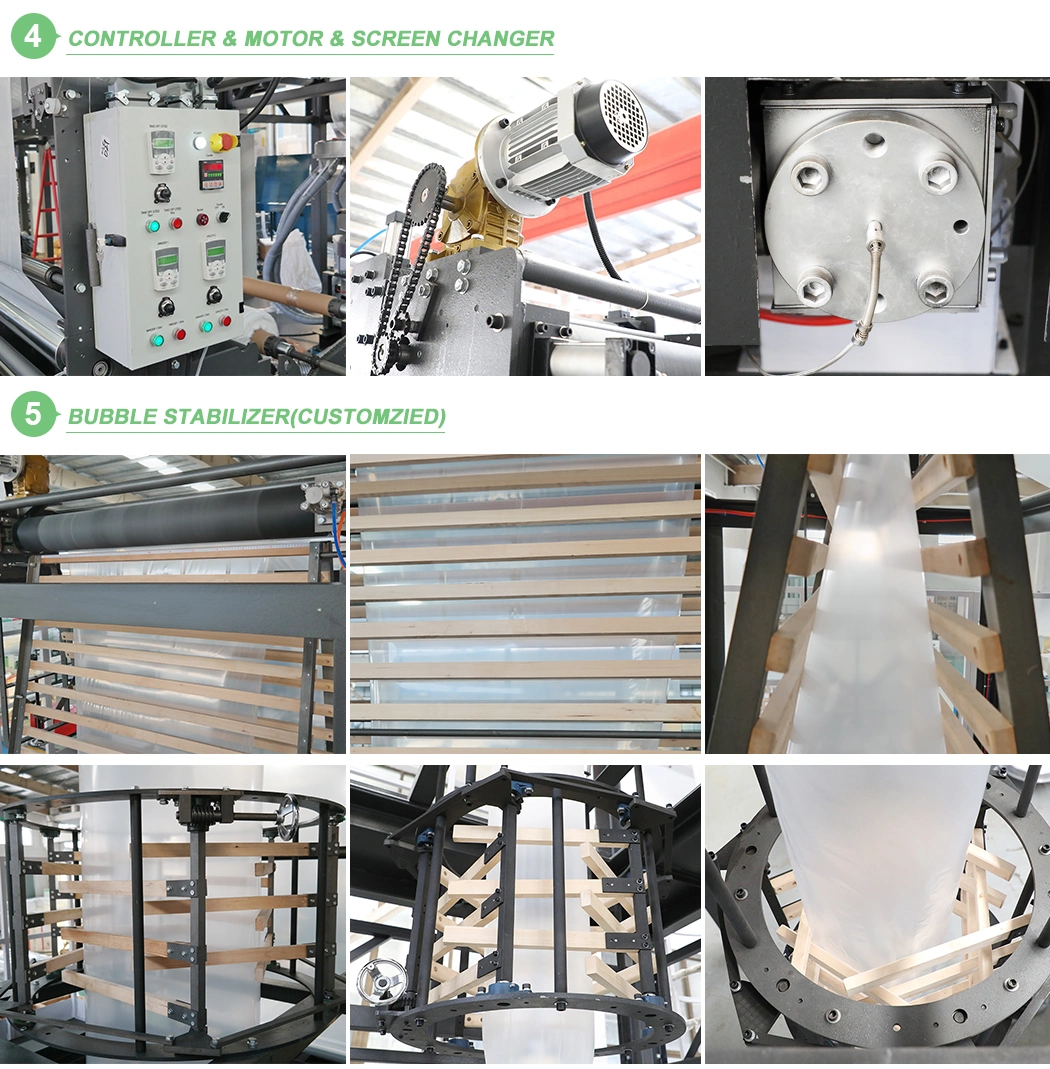

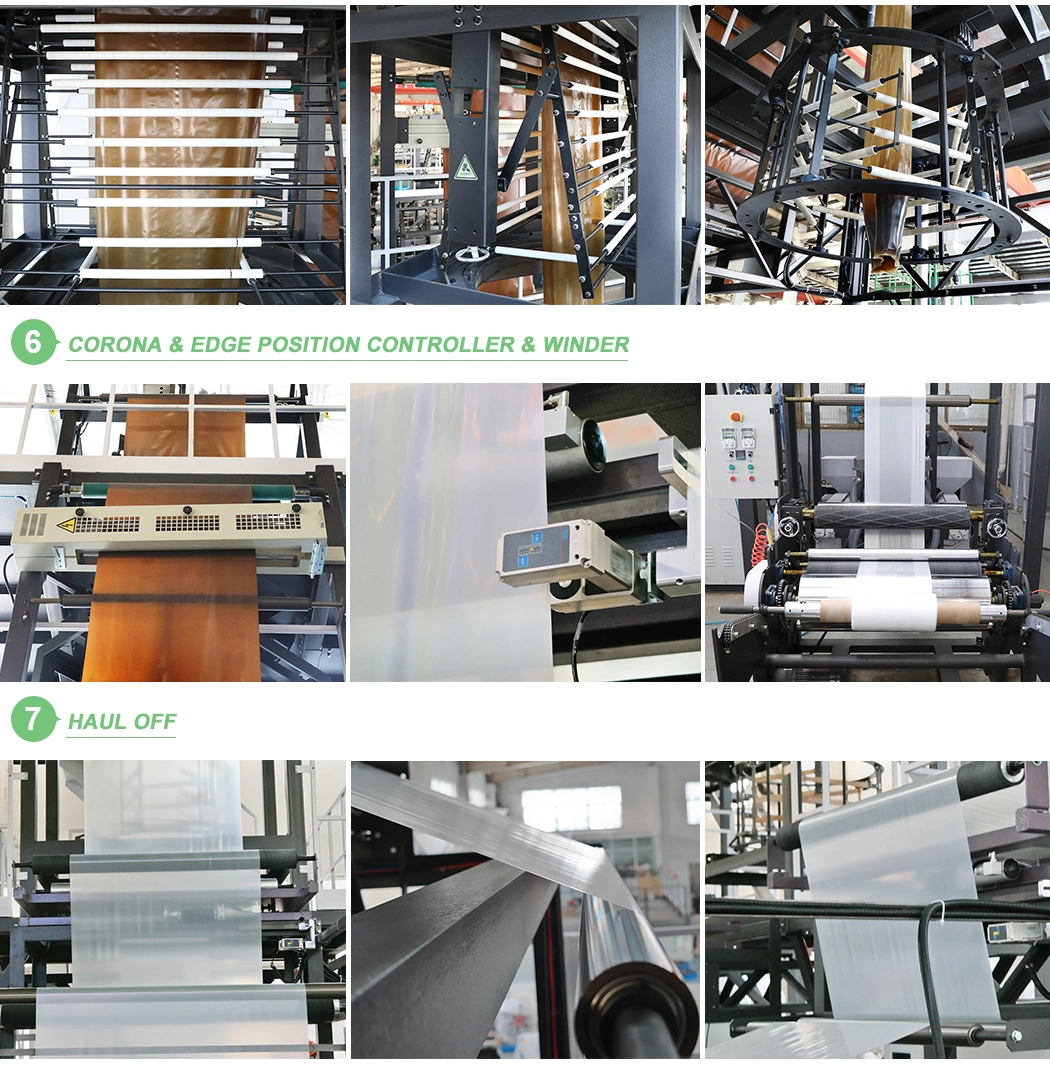

Double layer co-extrusion blown film machine1.Brief introduction:Ab double layer co-extrusion film blowing machine, energy saving, high speed and high yield, reliable operation.This type of film blowing machine is mainly for making underground film,construction film,water pouch,garbage bag etc.2.Features* Independent main extruder base + independent machine tower* Bimetal screw & barrel,L/D ratio 30:1* Standard type manual operation screen changer* PID + SCR thermo control system both for extruder & extrusion die* LH series high pressure double layer extrusion die with dual gap design* High effect LDPE dual lip air ring* High effective air cooling blower with air volume adjustor* Whole series with wooden stripe type bubble basket* SM type semi-manual surface friction winder + standard steel winding reel * 2

Product Parameters

Model | Roller width(mm) | Film width(mm) | Film output (kg/hr) | Main motor(Kw) | Die head(mm) | Cooling Blower(Kw) | Take up motor(Kw) |

CM-AB LD/LLDPE Double layer co-extrusion blown film machine (LDPE/LLDPE),0.015-0.20mm | |||||||

CM-AB35 | 800 | 400-700 | 25-60 | 7.5*2 | 150 | 2.2 | 0.75 |

CM-AB45 | 1100 | 600-1000 | 40-100 | 15*2 | 220 | 3.7 | 0.75 |

CM-AB55 | 1500 | 800-1350 | 60-150 | 22*2 | 300 | 5.5 | 1.5 |

CM-AB65 | 2000 | 1000-1800 | 100-220 | 37*2 | 380 | 7.5 | 1.5 |

CM-AB80 | 3000 | 1600-2800 | 200-350 | 55*2 | 600 | 15 | 2.2 |

Detailed Photos

Company Profile

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME* ACERETECH is original manufacturer.* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.* Each component before assembly needs strict control by inspecting personnel.* Each assembly is in charge by a master who has working experience for more than 15 years* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factoryTHE AFTER-SALE SERVICE OF ACERETECH MACHINERY* After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.* After the commissioning, we will package the equipment by the standard export package for shipment.* According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.* Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE ABOUT US, PLEASE CONTACT US