Automatic TTR Slitting Machine, Brand New Stretch Film Slitting Rewinder Machine

Basic Specification of Thermal Transfer Ribbon Slitting Machine High Precision AutomaticJumbo Roll Slitting Machine TTR

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 680 |

| Packaging | Film |

| Classification | Ultrasonic Label Cutting Machine |

| Applicable Process | Final Inspection |

| Suitable Substrates | Mica Tape |

| Packaging Material | Wood |

| Transport Package | Wooden Box |

| Specification | customized |

| Trademark | codewel |

| Origin | China |

| HS Code | 96121000 |

| Production Capacity | 200 |

Product Description

Basic Specification of Thermal Transfer Ribbon Slitting Machine

High Precision AutomaticJumbo Roll Slitting Machine TTR Ribbon Reel Cutting And Rewinding Machine

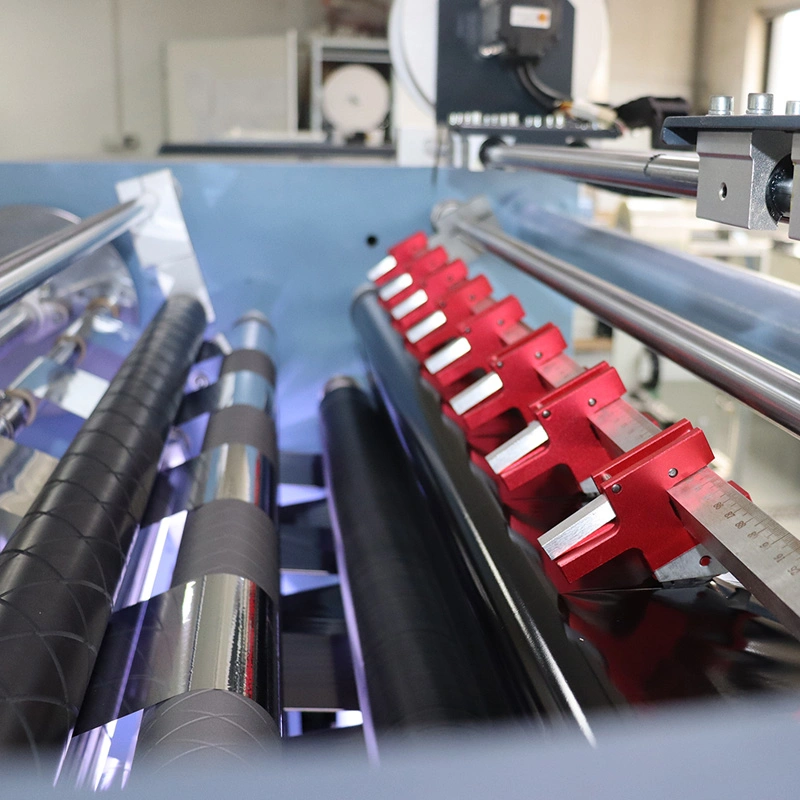

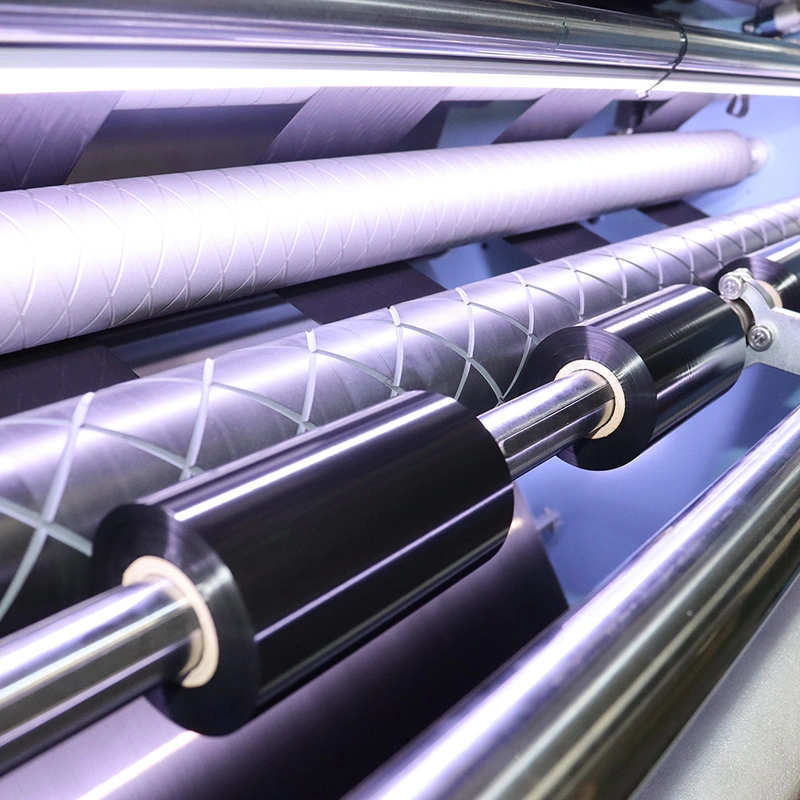

Automatic TTR Slitting Machine (Thermal Transfer Ribbon)

Model | TTR Slitting Machine 680 |

Max Working Width | 1010mm(Optional 1050mm) |

Unwinding Diameter | Max 650mm |

Unwinding Core | 6″ (shaftness) |

Rewinding Width | Min 25mm |

Rewinding Diamenter | N1:max 110mm,N2M, N3M:max 140mm |

Rewinding Core | 4 pcs 1" Air Shafts and 4 pcs 1/2" Air Shafts |

Blade Type | Magnetic Razor Blades |

Leader & Trailer Station | Semi-Auto (N3M Optional: Semi-Auto/Fully-Auto) |

Machine Well Thickness | N1:40mm;N2M, N3M:30mm |

Motor + PLC | Sanyo Servo Motor+SIEMENS PLC |

Mechanical Speed | N1:Max.280m/min, N2M: Max.300m/min N3M:Max.450m/min |

Working(slitting) Speed | N1:Max 250m/min,N2M:Max 300m/min, N3M:Max 400m/min |

Power Supply | 380V,50Hz,3 Phase (can be changed as required) |

(1)manipulate plate (2) height adjustment the handwheel(3) shrinkable film (4) installed shrinkable film device(5) shrinkable film fixed bar (6) tension membrane the clutch handle(7) circular shaft (8) shrinkable film openings set square (9) conveyor belt (10) urgent stop switch

(11) cover (12) shrinkable film openings set square (next)

(13)width adjustment the handwheel (14) photo-sensor

(15) adjust foot plate (16) sealing Knife

(17) traction motor (18) ShouFei switch

(19) connected platform (20) cutter cover shell

(21) budge switch function board

(22) film feeding on the horizontal bar (can fluctuate regulation) Figure

FUNCTION & FEATURES

WS888 automatic L-type sealing machine concentrates bag-molding ,sealing, cutting and object transmission in one operation; use shrink film as packaging materials. It has advantages of simple operation and high capacity. It is suitable for the need of big scale production. BS-D4525 thermal shrink machine is specially designed to combine with WS888 to shrink film after sealing. After sealing and cutting, products are transmitted into thermal shrink tunnel for shrinking.

• High capacity of 25packs/min

• Simple adjustment is done when packing size changes, no other assistant device is needed

• Packing of small size of objects is reached by functional choice

• Advantage of short sealing time and perfect sealing strength

• Adopt American "Dupont" Teflon coat for sealing cutter that hasfunction of stick-proof and anti-high temp.

• Automatic film feeding and waste film collection

• Vertical & horizontal photoelectric sensors are optional for differentobject

Related Products

-

![Dbry Series Flexo Printing Machine for Label Paper and Film Printing]()

Dbry Series Flexo Printing Machine for Label Paper and Film Printing

-

![LLDPE Film Rewinder PE Stretch Film Rewinding Machine POF PVC PE PVA Cling Film Rewinding Machine with 4 Air Shaft]()

LLDPE Film Rewinder PE Stretch Film Rewinding Machine POF PVC PE PVA Cling Film Rewinding Machine with 4 Air Shaft

-

![High Speed Multicolor Narrow Web Roll to Rollflexo Printing Machine for Paper, Film, Plastic Bag, Non Woven]()

High Speed Multicolor Narrow Web Roll to Rollflexo Printing Machine for Paper, Film, Plastic Bag, Non Woven

-

![All-in-1 4in1 Industrial Mobile Screw Air Compressor 10HP 15HP 20HP with Dryer Inside for laser Cutting and Packing Machine]()

All-in-1 4in1 Industrial Mobile Screw Air Compressor 10HP 15HP 20HP with Dryer Inside for laser Cutting and Packing Machine